An article about innovative technologies of “FOT-Capital” group of companies published in SKReview journal by Skolkovo Innovation Centre

|

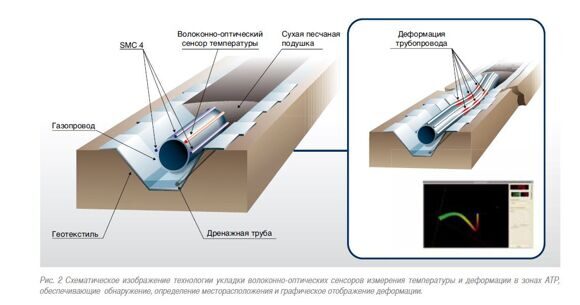

« Back 06.04.2014 22:00 “Braided Infrastructure: Adoption of Skolkovo Technologies in Russia” The first thing you may notice entering UFD (Unique Fiber Devices) office is the wall with several dozens of pattents (including one American) protecting rights of researchers and developers working here, and also showcasing an abundance of innovative ideas at this place. UFD is a Moscow-based company, and also a member of energy efficient technologies group, developed by major Russian scientific research Fund “Skolkovo”. Those technologies include optical fiber sensors and monitoring systems applicable in various infrastructures, starting from pipelines and electric power cables to roads and composite material structures. While the principle stimulus for evolution of fiber optic technologies was communications, today it has turned to data acquisition and analysis tool, says Anton Kuzin, CEO of “UFD”, CJSC in his interview to sk.ru: «The main job of a standard fiber optic cable, just like one wired in your apartment for internet connection, is to protect fibers from environment, temperature and strain effects. On the contrary, our task is to collect all ambient exposures to the sensing fiber whilst high bandwidth, accuracy and high data-carrying capacity are maintained. One optical fiber used as a fully distributed continuous sensor is equivalent to thousands of individual point sensors». Company “Unique Fiber Devices” established by researchers of Kotel’nikov Institute of Radio Engineering and Electronics of Russian Academy of Science (IRE RAS), Fryazino branch is R&D division of “Fiber Optic Technics-Capital” (FOT-Capital) holding. It also includes an engineering company “Laser Solutions” whose business concerns implementation of fiber optic systems on customers’ sites and manufacturing company “Fosens” located near Moscow in Podolsk. Today it’s a mature business that covers all development processes: from concept to production and system integration, using the latest cutting-edge fiber optic technologies that exist in the market. The history of UFD began from commercialization of fiber optic current and pressure sensor for power industry applications that was invented by scientists from Institute of Radio Engineering and Electronics of RAS. «Over some time we abandoned current sensors and focused on distributed fiber optic monitoring systems, says Anton Kuzin. – One of our latest successful developments fully demonstrating the nature of our business is a distributed acoustic system which transforms a standard fiber optic cable into a distributed microphone». It has extensive applications from safeguard systems (cable embedded in the soil responses to vehicle movements and walking activities pinpointing the exact location of the intruder) to downhole noise logging, which allows boosting hydrocarbon outputs. Another application of this technology relates to hydroacoustics. A dedicated fiber optic cable shows very good resistance to water and corrosion, so the system can be quickly deployed and used for both subsea border surveillance and detection of submarine objects and hydrocarbon exploration on offshore fields. «The physical principles behind fiber optics are as follows: probe signal is sent through an optical fiber, then target data can be obtained by spectral analysis of the backscattered emission, - explains Anton. – Part of the energy generated during propagation of the intense light pulse is scattered along the optical fiber. There are several types of scattering effects, particularly our acoustic fiber optic monitoring system is based on Rayleigh scattering». Rayleigh scattering is interaction between the light and inhomogeneities of the medium, which size is smaller than size of the wavelength (it is Rayleigh scattering off the molecules of the air which gives us the blue sky). When measuring strain and temperature of extended facilities, such as, transmission pipelines and oil & gas wells Brillouin Scattering is used instead of the Raman. Strain and temperature changes of the extended facilities and real-time 3D positioning are achieved through sets of sensors attached to the pipeline. Such configuration provides control of pipeline behavior, position in space, temperature, leakage detection and ground movements along its entire length. The gathered measurements are processed and if any deviations from the preset parameters occur, the engineers and operators can get an instant alarm signal about the anomalous event. The largest orders for such applications supported by developers and engineers of “FOT-Capital” holding became Gazprom projects in the Far East of Russia. In 2011 Gazprom commissioned first startup complex of Sakhalin-Khabarovsk-Vladivostok Gas Transmission System. It is forecasted that by 2020 the capacity of the pipeline will reach 30 cubic meters of natural gas per year. More than 1800 km of the pipeline route is crossing unstable terrain in remote areas caused by seismic activity and geological hazards. Due to scalability of the project, a Distributed Fiber Optic Geotechnical Monitoring System for gas transmission pipeline was developed. The sensor attached to the pipeline is about 300 km length. «Overall system includes 3 components: analyzer, fiber optic cable and software for analysis and visualization of the incoming data, - Anton Kuzin admitted. – A user-friendly interface of our system makes our technique more broadly available and easy, so the operator doesn’t need to be a scientist to work in it». It took 3 years to convince Gazprom representatives in efficiency of fiber optic sensors, recalls Anton to sk.ru: «Innovations do not easily catch on in Russia. We’ve been attempting to adopt our developments to different industries, but oil & gas turned out to be much more open to modernization, so the idea of minimized operating costs, ecological impact and technological advances offered by our innovative technologies has reached this customer more effectively». Another ongoing R&D project that has been carried out by the resident of Skolkovo in Yamal-Nenets Autonomous District since the middle of last year is connected to a growing popularity of the “smart field” concept that has gained momentum within oil & gas industry throughout the world. In addition to multitasking the approach includes continuous downhole monitoring. Mr. Kuzin is convinced that development of the extractive industry is impossible without fiber optic technologies: «Rapidly growing demand in uninterrupted control of facilities had been recognized by foreign companies, for example, in US. As for Russia, we are just taking first steps in this direction». The main competitors who take on downhole projects in Russia are basically large foreign oil service companies. UFD CEO assures: «Our most competitive advantage is our price. First of all, we produce our sensors in Russia which makes them cheaper. Secondly, our know-how involves better resistance of optical cable to aggressive environment in the well, such as radiation, hydrogen, etc. Competitors have to bypass these complexities using their specific methods, causing an actual increase of price». Currently UFD is putting every effort in development of distributed sensor for downhole application which, as estimated by Anton Kuzin, is promised to be a real breakthrough in extractive industry. Yet such sensor doesn’t even exist and if oil & gas engineers be able to measure hydrostatic pressure along the wellbore they will have a much deeper understanding of in-depth processes which will consequently result to increased hydrocarbon output. Compact logging sensing cable combining high accuracy with the long-range will allow controlling oil & gas well behavior along the entire lengths. «Oil shut-ins or reduced rate of recovery forces operators to shut down the well for logging surveys. An optimal way to quickly obtain direct data would be a real-time and continuous well monitoring, but it can’t be met with the existing technologies (apart from fiber optics). The main parameter that should be analyzed is pressure», - Anton Kuzin explains. He assures us that the relevance of fiber optic pressure sensor development was justified during negotiations held between the executives of UFD and several potential customers, including one large foreign oil service company. High potential of this idea was also evaluated by Skolkovo Foundation. So, last year the company’s project was supported with 46 MM rubles splitted up between Skolkovo and «Fiber optic technics-Capital» holding. For “Unique Fiber Devices” getting a grant from Skolkovo Foundation is not only about financial support. «Skolkovo Foundation helps us to establish contacts with potential customers. It is very useful and these contacts inspire us for interesting ideas, - Anton tells. - Skolkovo has brought us to participate in several events, including Startup Village, presentation of our project to investors, Arctic Exploration and Production trade show and conference, which helped us setting up very useful business contacts». Another promising application which is now examined and sized up by Skolkovo startupers is composite pipelines. Not even once Gazprom’s executives have shown their interest for replacement of traditional metal pipes for composite pipes that will enable to prevent corrosion among other threats to the pipeline integrity. The interest has not yet turned out to practice, but UFD expect that the situation will change in the nearest time: «This would be very attractive and we would like to take part in this project of Gazprom if it is ever implemented. If sensors are integrated during the design stage, you can get a complete “smart” monitoring solution», - said Anton. Optical fiber is very adjustable to the structure of composite materials and show excellent performance when exposed to high temperatures during manufacture. The developers are experienced in installation of fibers to a composite bridge which demonstrates that their technologies are compliant to similar tasks.

One more project on a similar stage (test prototypes have been developed, but integration agreements are not signed) is an electrical power project for development of “smart” phase wire. «Optical fibers are widely used for temperature control of underground cables and data transfer. Power engineers have not once expressed their interest in getting a smart phase wire. So we started working on prototypes and now they have been released, - told Anton. – Fiber optic sensors integrated to a phase wire provide temperature and strain measurements which makes it applicable for monitoring of overheadline integrity, particularly line ruptures, icing, sagging and overheating. Last autumn we designed a pre-production prototype and we use every opportunity to advertize it. Similarly to other applications it’s not an easy thing to do; additionally it can be, to some extent, explained by reorganization of electric power industry in Russia». Second large and perspective industry after oil & gas that takes into account the vast territory of Russia is transport infrastructure, specifically railroads and highways. To ensure safe operation of railroad transport in rail traffic management system, an integrated continuous monitoring system that will provide strain control at most critical sections of the roadbed, such as bridges, tunnels, rockfall and landslide areas, soil erosion, is of vital importance. The proposed monitoring solution consists of three main components: analyzer, a distributed fiber optic sensor and a dedicated SW. Analyzer is a powerful diagnostic instrument with distance range up to 70 km per channel (140 km in two opposite directions from the analyzer. The number of measurement channels can be extended by using an external multiple optical switch module. Once an external switch is connected to the analyzer, up to 21 sensors can be used for distributed sensing. Sensor is an uninterrupted fiber optic cable that is customized for a specific application, which makes it a valuable solution to numerous point sensors. Anton Kuzin exemplifies the benefits of the revolutionary approach: «Taking into account high spatial resolution of the analyzer each 50 centimeters of sensor can be considered as an individual point sensor, therefore 50 centimeter sensor section is equivalent to 100 000 point sensors»

The original text in Russian is available here: http://community.sk.ru/news/skreview/

|